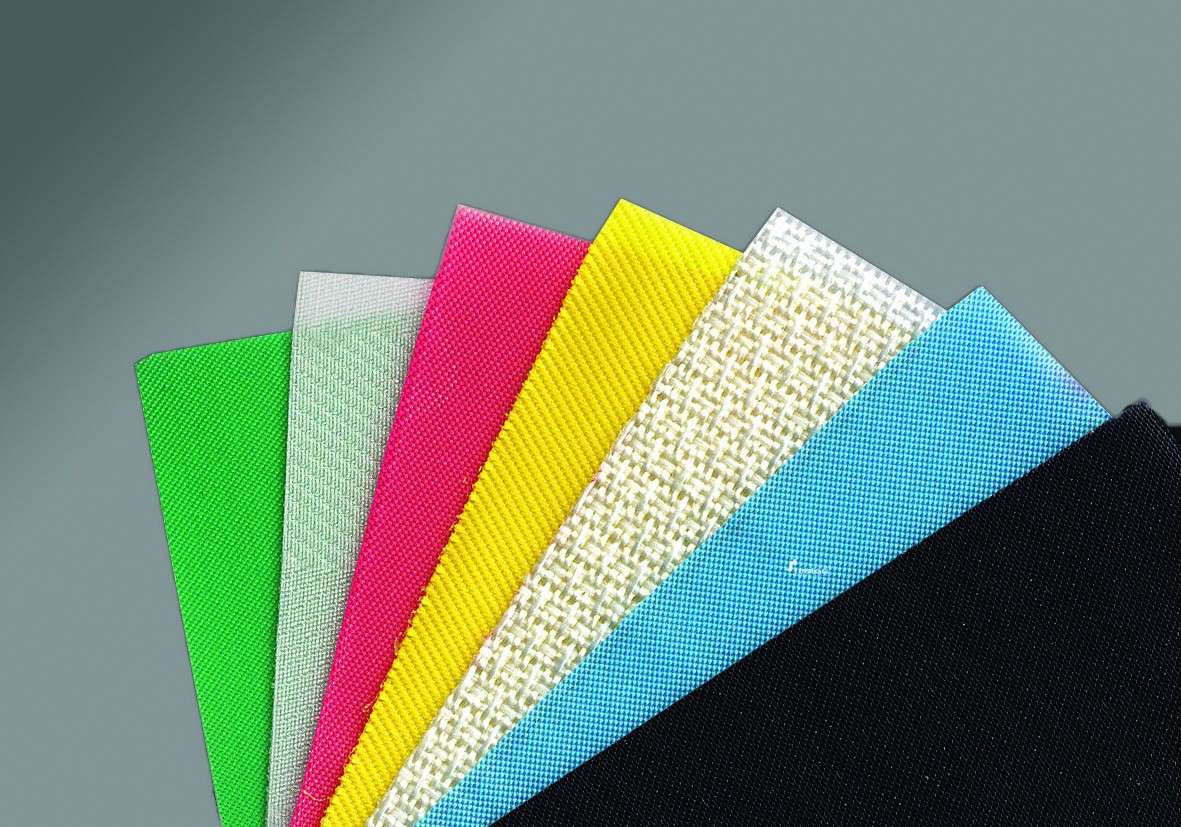

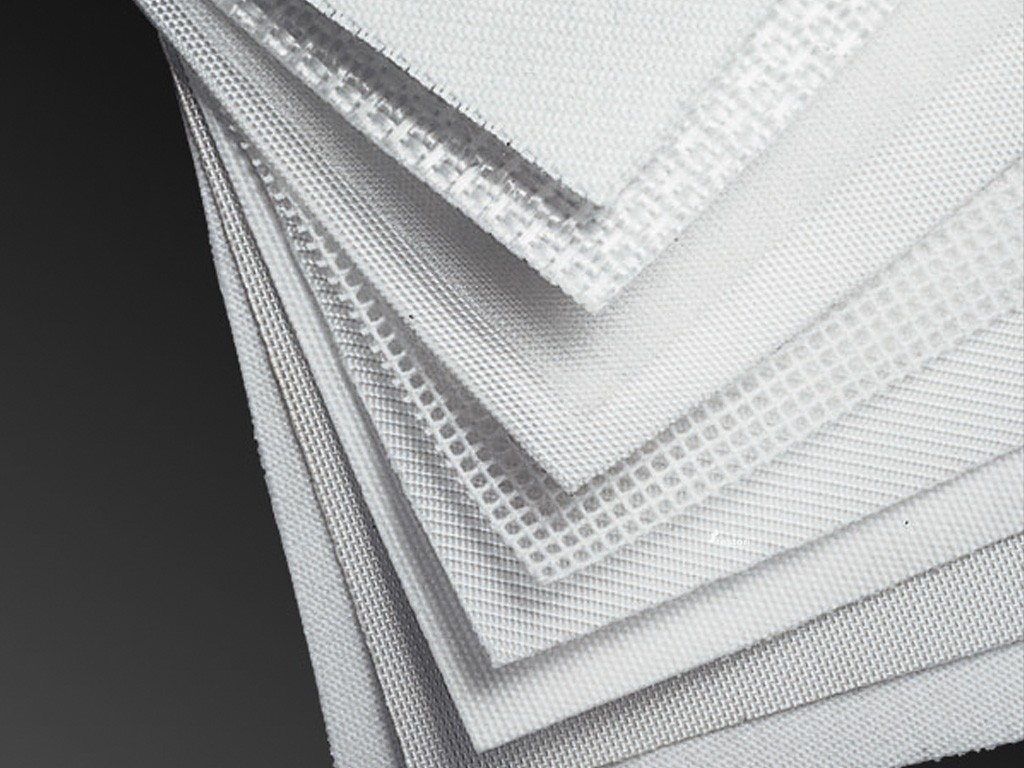

Woven fabrics

Wide range of wovens and felts to meet all different needs of each production process.

Testori filter media offering ranges among various types of polymers (polypropylene, polyester, PBT, all grades of polyamide, PTFE, etc.) and type of yarns (mono, multi, staple fiber).

According to the process needs, Testori can design a tailor-made fabric for superior performance. Thanks to the lean, flexible, and vertically integrated operations, we can ensure ultimate level of service along with top quality assurance.

Excellence of Testori's proposal in liquid filtration, they are used in many sectors, from mining to water treatment, food, chemical and pharmaceutical industries, ensuring full satisfaction and optimal performances to our customers.

Type of cloths

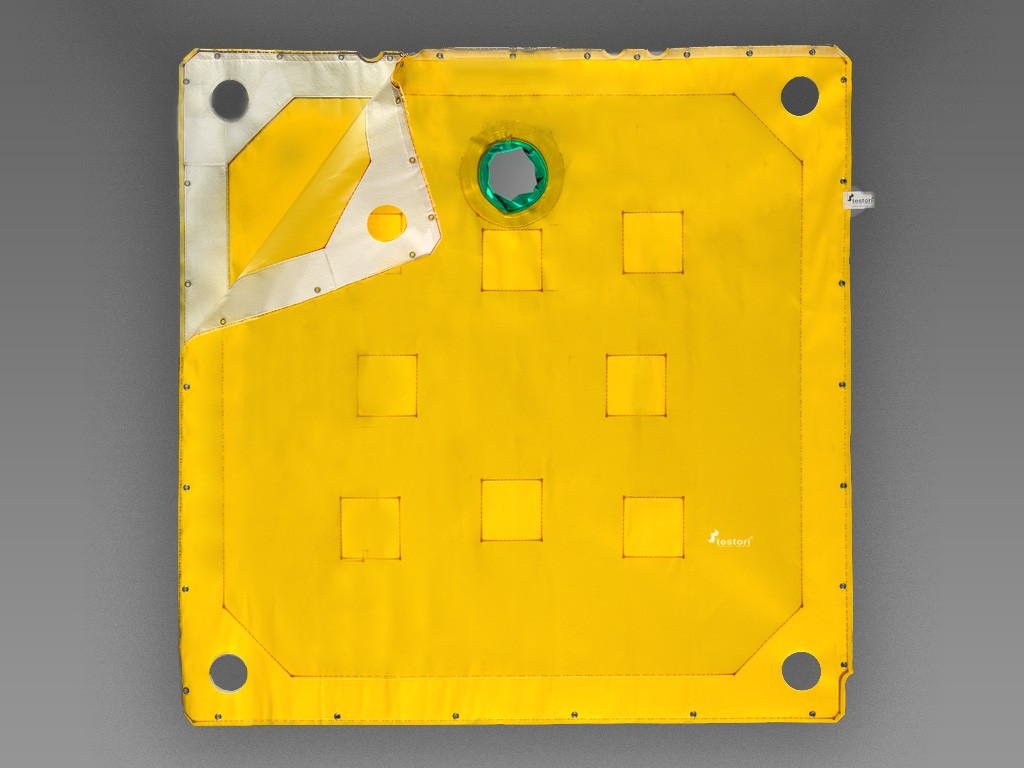

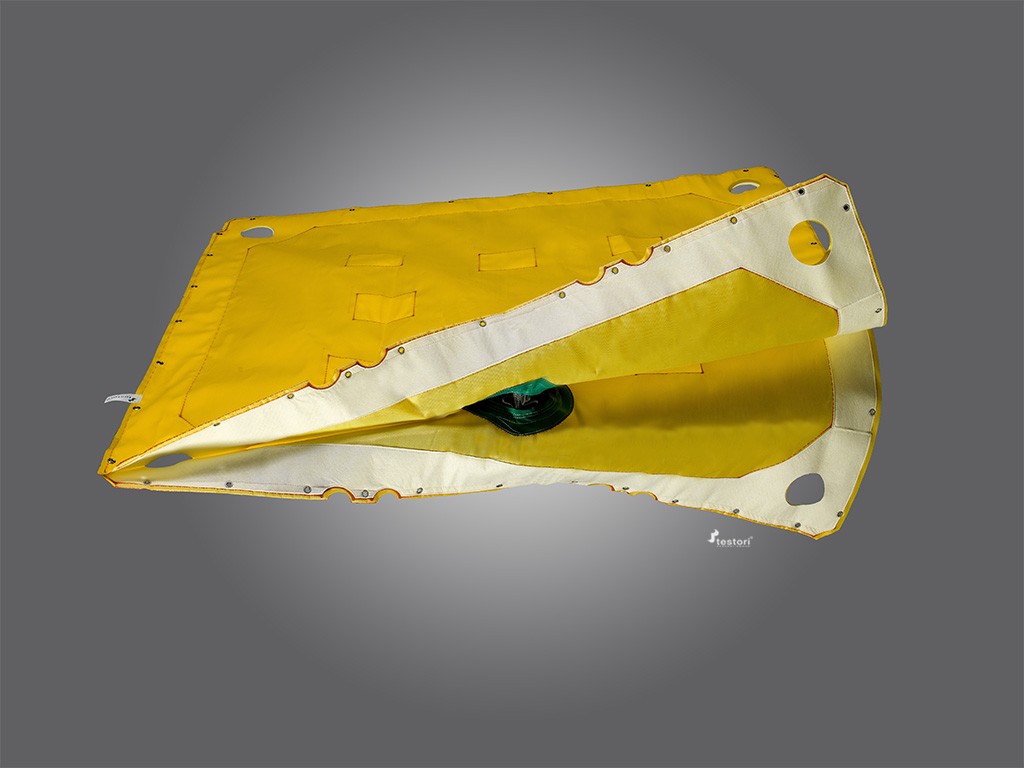

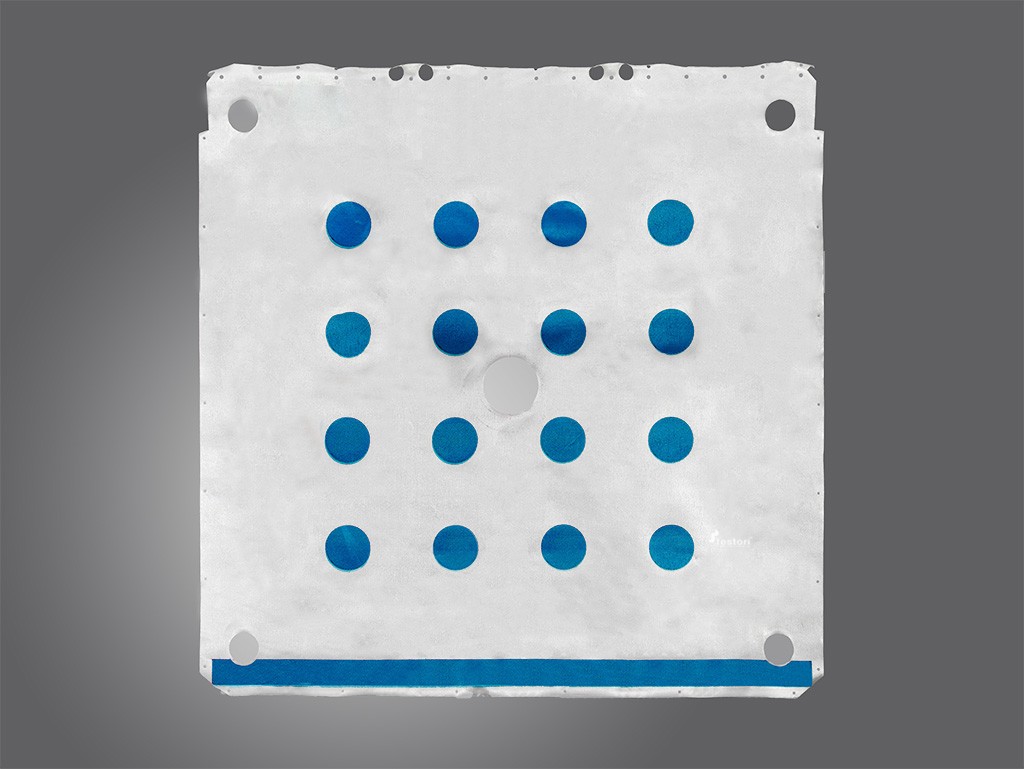

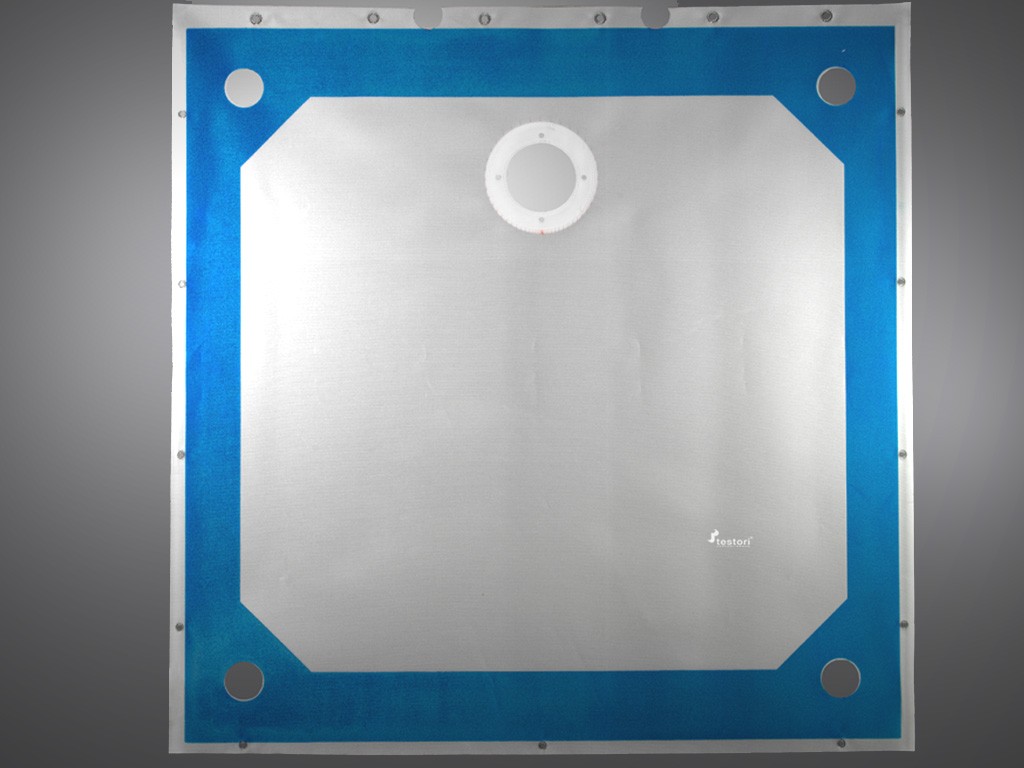

Thanks to the consolidated experience and continuous collaboration with the major OEMs on the market, Testori follows the technological evolution of the sector, offering filter cloths able to satisfy the most severe dimensional and performance requirements imposed by the latest different models of filter press horizontal axis: single plies, twin plies with collar, straddle plies, with shaking bar, with gasket, etc.

Special features

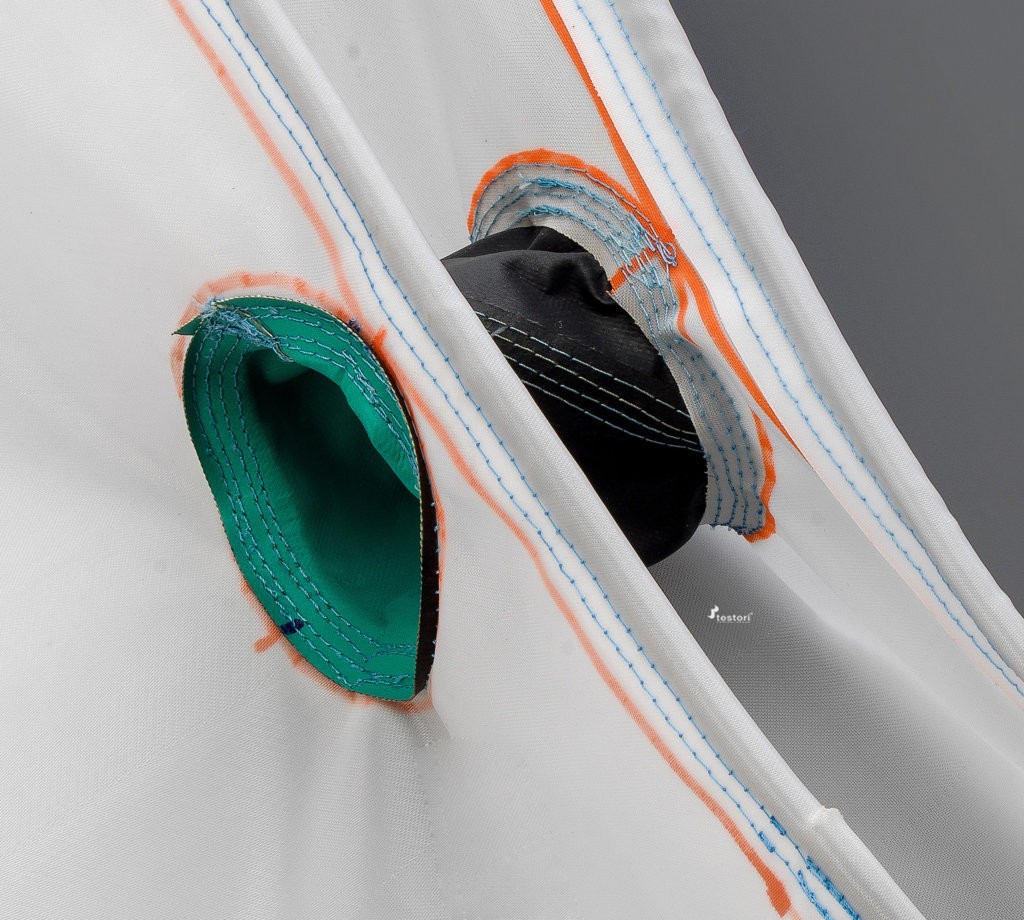

Each process is characterized by specific operating conditions that might require the implementation of special features to extend cloth lifetime, preventing premature damage or failure, affecting the overall productivity and effectivenessof the filter.

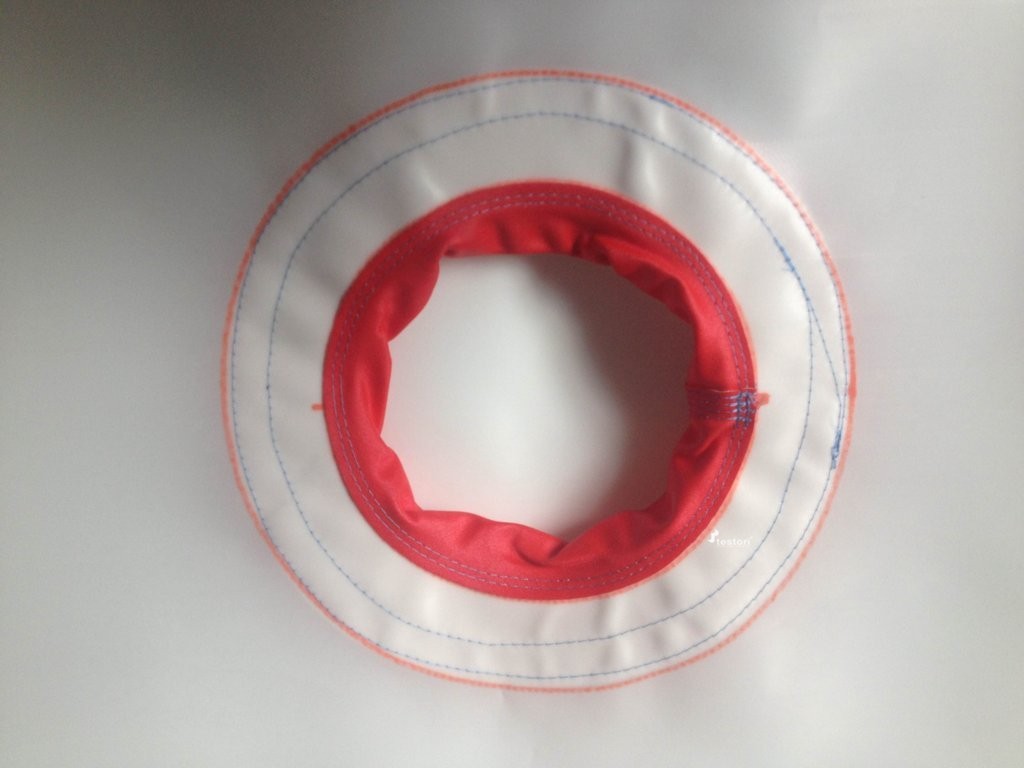

- Resispam treated distribution ring reinforcement and barrel neck to withstand severe abrasion caused by inlet feed sludge

- Anti-Corrosion Eyelets to withstand chemical abrasion, available in the same polymer as the filter cloths medium

- Perimetral impervious resin, also FDA approved, to prevent filtrate spillage outside the chamber. Also available on backing cloths.

- Reinforcements made in needlefelt or woven fabrics on the frame and boss heads to prevent premature mechanical decay deterioration.

Unique range of fabrics dedicated to sugar, chemical and alumina refining industries capable to ensure high specific throughputs, superior filtrate quality and thickening ratios.

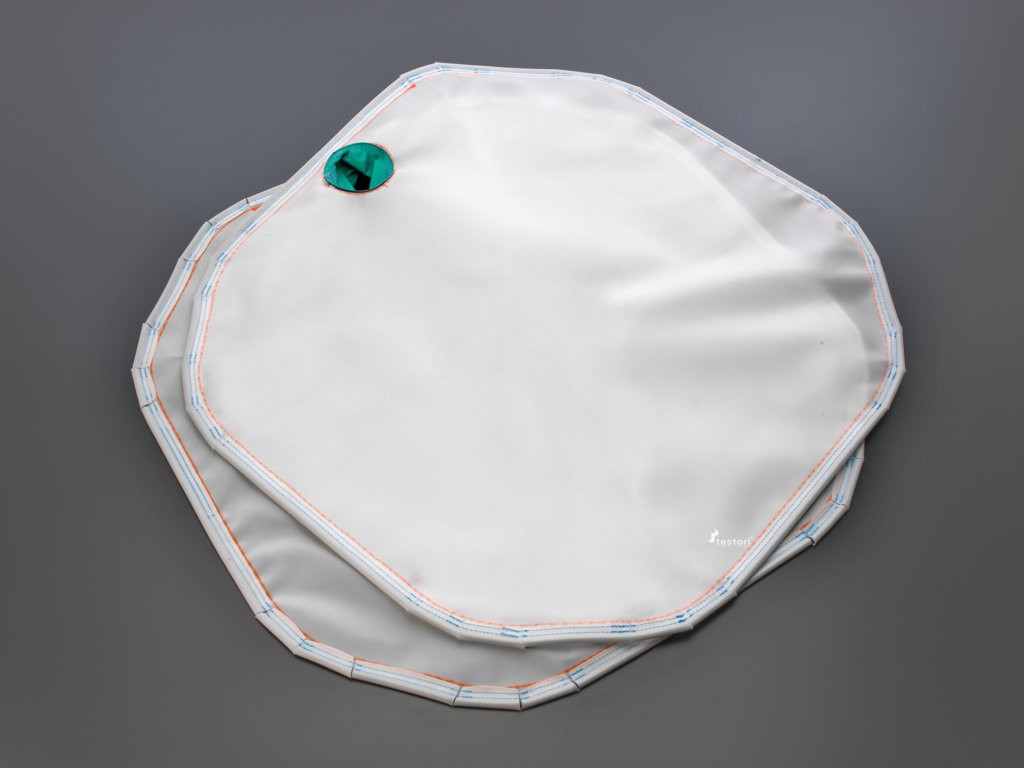

Consolidated manufacturing experience capable to- create bags of all sizes and configurations

- Enrich the bag with distinctive tailoring details, such as the wear-resistant upper flap that guarantees greater durability

- Enrich the bag with distinctive packaging details, such as the wear-resistant upper flap that guarantees greater durability

- Adapt to requests for special features to meet the rigorous and demanding requirements of each production process.

Testori product range offers:

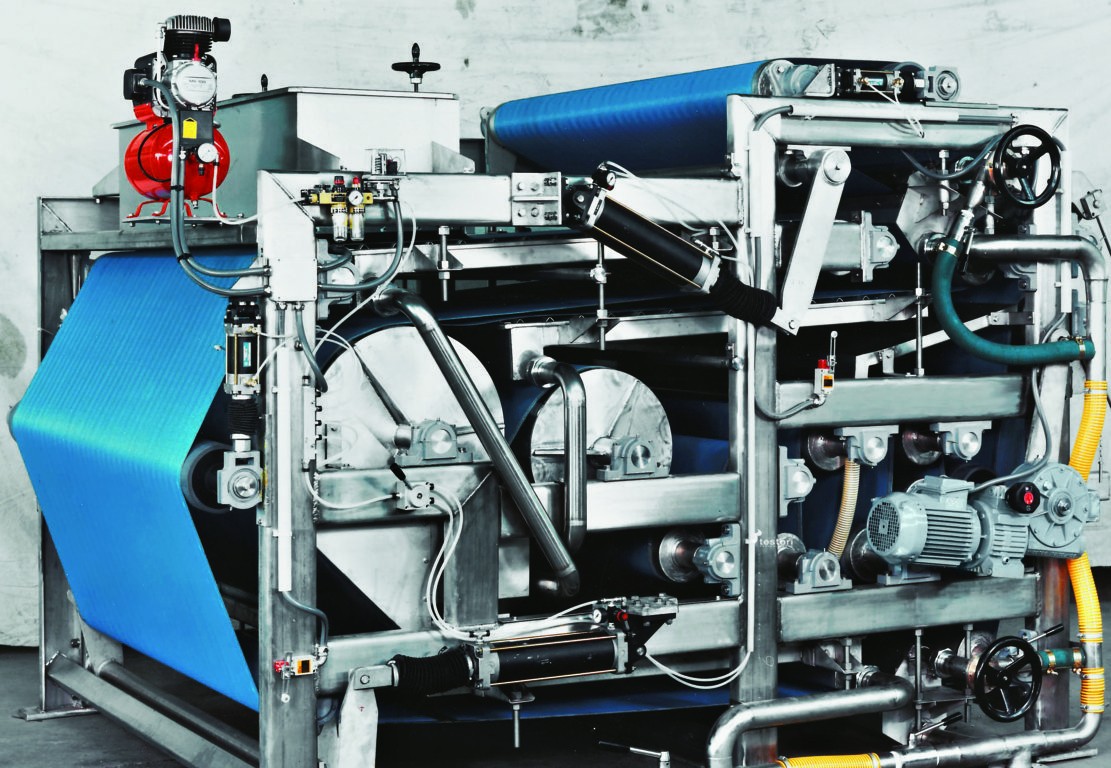

- High drainage mono/mono fabrics capable to provide low residual humidity cake.

- Stainless steel clipper joint and special coating to ensure proper sealing of the belt.

- High tenacity yarns to ensure dimensional stability of the belt.

Testori, the solution for every application

#test-us